Before investing in any of the various brands, you must be familiar with the main aspects to consider. In addition to the printer, materials and software are required for successful 3D printing. It is imperative that you assess your needs and choose a printer with the optimal features for your business.

How does 3D printing function? is the initial question that must be addressed. This way, you can determine the needs of the firm prior to investing money. Understanding the fundamental aspects of the trade is essential for making the best investing selection. Some of the most important variables to consider when purchasing a 3D printer are presented here.

Use

Prior to purchasing a 3D printer, you must carefully consider its intended application. As decided by the application, the models available on the market have distinguishing characteristics. Some of the units are designed for domestic usage, while others are intended for industrial use. Before placing an order, you must understand why you need the machine. If you want a successful 3D printing experience, you must establish your goals from the beginning. Thus, you are able to acquire an item that meets your demands without difficulty.

Manufacturer

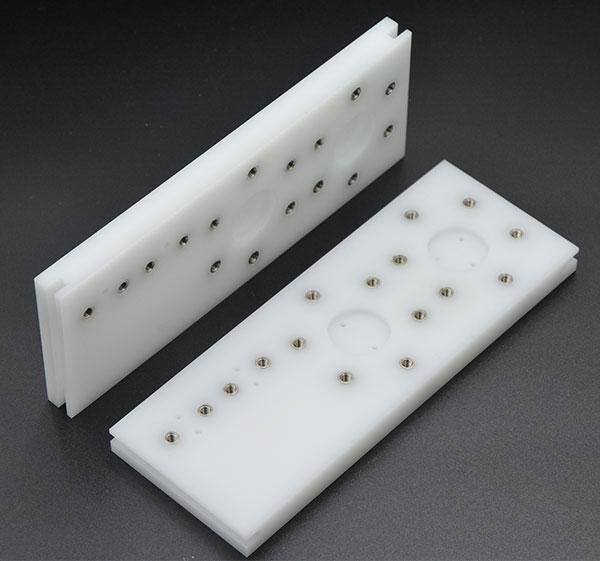

Consumers can purchase 3D printing machines and CNC machined parts from a variety of manufacturers. Some have extensive experience in the industry, while others are newbies. Long-established brands have endured the test of time, and you may be confident in the product’s quality before placing your order. Confirm if the producing company sells premium products by examining its past performance. In addition, they should offer a responsive and professional customer service department to assist you if you get stuck while using the equipment or have questions you need answered before purchasing a 3D printer.

Read evaluations and comments

Experts in the field of 3D printing evaluate the available equipment on the market. Before deciding on a unit, read their evaluation and learn more about the product. In addition to expert reviews, consumers provide input regarding their experience with a given model. Examine both positive and negative reviews to gain a better knowledge of the product you wish to purchase.

In addition to the factors discussed above, it is vital to assess the print bed’s size, calibration, software, filaments, and unit cost.

Four effective 3D typographic tools

3D printing services are defined as the process of creating a three-dimensional object from a CAD file or digital 3D model.

Here are some instances of modern applications of 3D printing.

1. Decorations

3D topography is sweeping the universe, pushing various companies, including those utilizing lost-wax casting technologies and jewelry manufacturing, in competition.

3D typography puts out resin wax bits based on a model. People enjoy gaudy objects, and the 3D support has proven to be terrific. They are capable of doing so. Profitable and efficient, 3D typography has zero errors and a quick response time. As a result of technical development, new opportunities have evolved.

2. Spare parts

This appears to be valuable for creators as well. For them, missing or cut-off fractions might be problematic, but 3D typography has eased the process. It is inexpensive for low-volume production. As 3D printing allows them to manufacture ingredients directly, forms have begun evaluating novel repository approaches; they require a digital design.

3. Shoes

Sneaker enthusiasts would enjoy this. Money can be redeemed by purchasing 3D-printed footwear. You can also create a layout and release it immediately. 3D typography facilitates the development of intricate hierarchies that boost alert absorption and decrease shoe luggage. We all have several shoe extensions, and shoes in sizes 13 and 12 were particularly difficult to locate, stopping you from acquiring the desired footwear. Shoemakers can establish tiny or medium custom fractions for athletes and tailor shoes for customers using 3D printing.

4. Outsourcing

Onshoring is the process of transferring a firm that has been relocated overseas back to the country in which it was originally founded. CNC services enabled this to be possible. Companies used to reallocate processes in order to reduce labor costs. Receiving the goods would be costly, and doing so in other countries would not ensure that they were well-made, resulting in defective goods. With 3D proving advantageous, the relocation was a prudent decision that restored faith in the inner creativity.